Extrusion Line

CV – Extrusion

MWEL use 2 John Royle 15-1 CV extruders, coupled with up to 70 meters of high-pressure steam and water pipes. This enables us to produce cable up to 15mm diameter in all types of elastomeric compounds as well as silicone. Both lines are fully automated to ensure optimum quality and diameter control.

The steam curing process enables maximum bonding / lock down between insulation, with or without reinforcing branding / minimizing sheath tear and maximizing terminal retention. Thus guaranteeing high Newton scale pull off strengths that cannot be achieved by any other curing process.

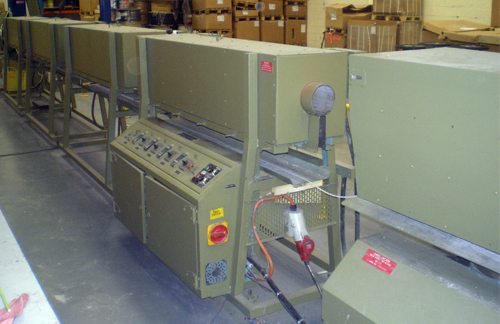

Infrared extrusion

Along these two CV extruders, Madison Wire (Europe) Ltd. has installed and commissioned a 70mm Halstead Extruder together with a 60ft (18.18m) infrared curing process, enabling the manufacture of high temperature silicone insulated cables for use within the automotive industry and many other industrial applications where there is a requirement to withstand high temperatures whilst maintaining flexibility together with the many other benefits that only silicone can offer.

The flexibility of this line enables us to manufacture to customers varying quantity requirements. As always we offer our customers the choice of colours, conductors, braided or unbraided and individual printing requirements.

The line is fully automated and equipped with a laser measurement system to ensure our high quality is monitored ad maintained throughout the production process.